welcome to our company

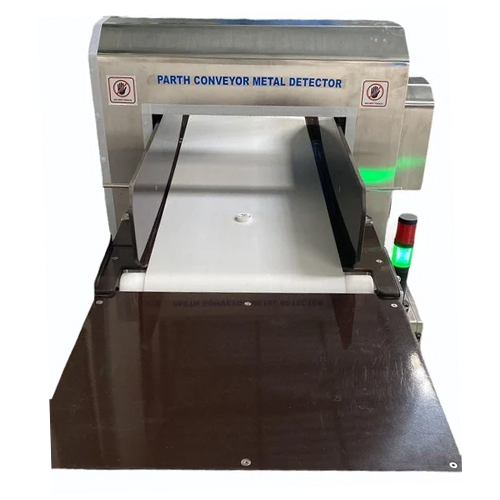

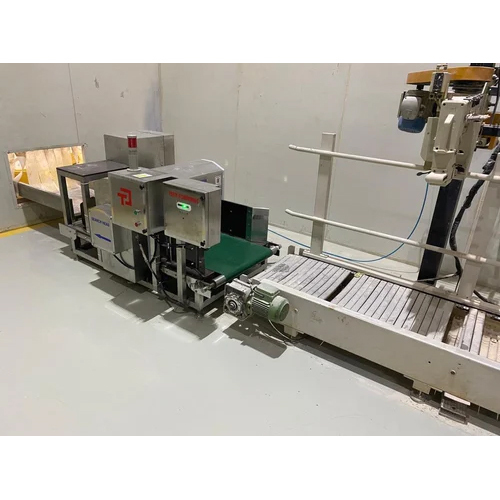

Incline Conveyor Metal Detector

Product Details:

- Frequency 50-60 Hertz (HZ)

- Function Detects metal

- Alarm Sound

- Power Supply Electric

- Material Stainless Steel

- Usage Industrial

- Rejecter Pneumatic or Flap-type Auto Reject System

- Click to View more

X

Incline Conveyor Metal Detector Price And Quantity

- 1 Unit

Incline Conveyor Metal Detector Product Specifications

- Yes

- Pneumatic or Flap-type Auto Reject System

- Stainless Steel

- Industrial

- Electric

- Sound

- 50-60 Hertz (HZ)

- Detects metal

Incline Conveyor Metal Detector Trade Information

- Cash in Advance (CID)

- 10 Unit Per Month

- 2-10 Days

- All India

Product Description

The Incline Conveyor Metal Detector is a reliable industrial solution designed for detecting metal contaminants in various production lines. Crafted from durable stainless steel, it combines robustness and efficiency, ideal for long-term use in demanding environments. Powered by an electric supply, it features a waterproof build, ensuring seamless operation in humid or high-moisture conditions. The detector is equipped with a pneumatic or flap-type auto reject system for precise removal of contaminated products, enhancing overall safety and quality. Operating at a frequency of 50-60 Hertz (Hz), the system alerts users with a sound alarm upon detecting metal, making it highly reliable for quality control processes. This product is an essential component for industries looking to maintain stringent safety standards and ensure product integrity.

FAQs of Incline Conveyor Metal Detector:

Q: What type of materials is the Incline Conveyor Metal Detector made of?

A: It is made of durable stainless steel.Q: Is the Incline Conveyor Metal Detector suitable for wet or humid environments?

A: Yes, it is waterproof and can operate effectively in humid or high-moisture conditions.Q: How does the system handle detected metal contaminants?

A: It uses pneumatic or flap-type auto rejecters to accurately remove contaminated items.Q: What alerts are provided when metal is detected?

A: The system uses sound alarms to notify users when metal contaminants are identified.Q: What is the operational frequency of the Incline Conveyor Metal Detector?

A: It operates at a frequency of 50-60 Hertz (Hz).Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese