welcome to our company

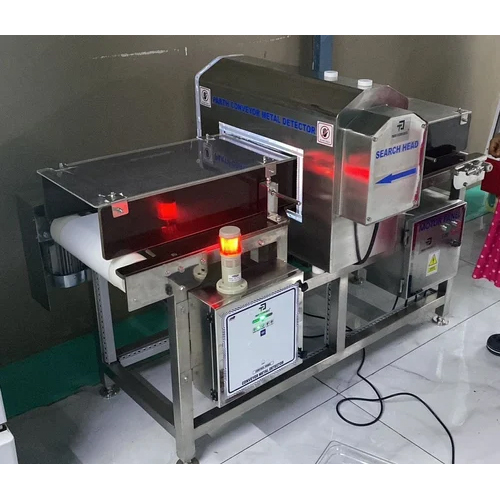

Textile Garment Conveyor Metal Detector

250000 INR/Unit

Product Details:

- Input Power 230 Volt (V)

- Function Detects metal

- Power Supply Electric

- Material Stainless Steel

- Frequency 50 Hertz (HZ)

- Usage Industrial

- Alarm Vibration

- Click to View more

X

Textile Garment Conveyor Metal Detector Price And Quantity

- 250000 INR/Unit

- 1 Unit

Textile Garment Conveyor Metal Detector Product Specifications

- Detects metal

- 230 Volt (V)

- 50 Hertz (HZ)

- Industrial

- Vibration

- Electric

- Stainless Steel

Textile Garment Conveyor Metal Detector Trade Information

- Cash in Advance (CID)

- 12 Unit Per Month

- 2-10 Days

- All India

Product Description

The Textile Garment Conveyor Metal Detector is an industrial-grade solution designed for detecting metal contaminants in textile and garment production lines. Constructed with durable stainless steel, this machine operates at a frequency of 50 Hertz (Hz) and utilizes a 230 Volt (V) electric power supply, ensuring efficient and reliable performance. Equipped with a vibration alarm system, it promptly alerts operators upon detecting metal to prevent potential damage or contamination in the production process. Ideal for manufacturers and suppliers, this metal detector enhances quality control and safeguards product integrity. Its conveyor-based functionality enables seamless integration into factory workflows, making it an indispensable tool for textile and garment industries focused on precision and safety.

FAQs of Textile Garment Conveyor Metal Detector:

Q: How does the metal detector alert operators?

A: The Textile Garment Conveyor Metal Detector uses a vibration alarm system to notify operators of detected metal contaminants.Q: What material is used for constructing the metal detector?

A: The metal detector is constructed from high-quality stainless steel for durability and reliability.Q: What is the input power required for the metal detector?

A: The metal detector operates on an input power of 230 Volt (V).Q: Is this metal detector suitable for industrial use?

A: Yes, this metal detector is specifically designed for industrial applications in the textile and garment sectors.Q: What kind of power supply does the metal detector use?

A: The metal detector is powered electrically, ensuring consistent and uninterrupted operation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese